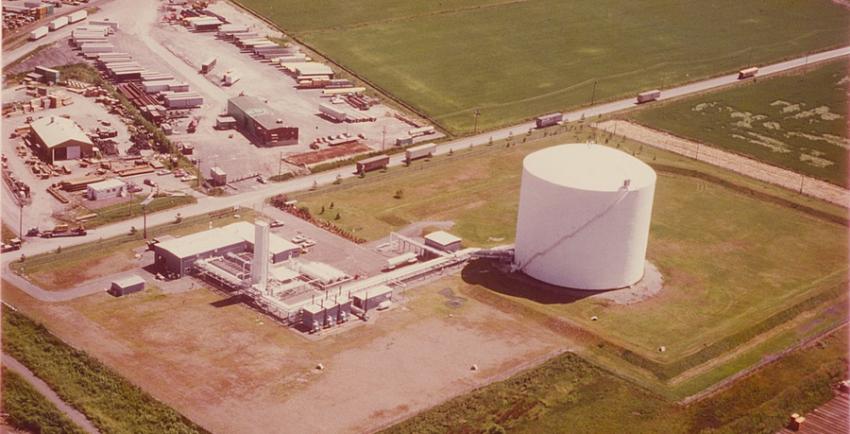

When the Tilbury facility launched, little was known about liquefied natural gas (LNG). Tilbury’s sole purpose, according to the Province, was to be a peak shaving plant—to store natural gas in liquid form until it was needed during times of peak demand.

The low-key introduction to Tilbury was in line with the public’s perception of the facility, says Stan Ballance, Tilbury’s operations manager from 1992 to 2010. “It was pretty low profile,” says Stan. “Tilbury was strictly known as a facility that stored LNG. It wasn’t widely understood that LNG is just natural gas that’s been condensed and stored in liquid form—the same natural gas we use to cook our food and heat our homes.”

Having the ability to store extra natural gas until it was needed on cold winter days, when demand was greatest, was a huge cost savings because demand charges on certain parts of the pipeline system were quite steep. “I remember the company saving millions of dollars every year—savings which could then be passed along to our customers,” says Stan.

The six-person Tilbury operations team never knew when they’d be called upon to put extra natural gas into the pipeline, through a process called send-out, but they were always ready. “We made sure we had the tank full by November 1,” says Stan. The number of times a year they would need to do send-out would vary depending on the severity of the winter, Stan explains, and it would often happen in the middle of the night, or early morning, when temperatures dipped. “When the call came in we’d jump into action. We could pump gas into the system within about two hours,” he says.

Jim Cox worked at Tilbury starting in the early ’90s and took over as operations manager when Stan retired. He recalls the long hours the team put in and their dedication to making sure the plant operated safely. “There was a very strong sense of ownership among the team and we had each other’s backs,” he says. “You could say, we were working for each other.”

Jim attributes the facility’s stellar safety record, in part, to the team’s diverse experience and how well they all worked together. “Everyone had come up through the ranks in different parts of the company,” he says. “We were able to draw on everyone’s strengths very effectively.”

Teamwork was never more evident at Tilbury than during the Enbridge pipeline rupture in October 2018. With the interruption to the Lower Mainland’s gas supply, Tilbury was put on notice to “get ready” to do send-out in case it was needed. It was a little earlier in the year than they would normally be expected to prepare, says Jim, but the team pulled together.

“It wasn’t another day at the office,” he says, tongue-in-cheek. “There were some things we needed to do fairly quickly to get the plant ready, but everyone did what they were trained to do.”

Jim admits that the uncertainty of whether or not they would need to add natural gas to the system and having to be on stand-by, made things kind of exciting for a while. “It never materialized, but we were ready for it,” he says.

Both Jim and Stan recall that by the late ’90s the uses for LNG began to expand, including in small remote communities across the province that wanted to try it out as a power source. Tilbury began shipping its LNG in specially built tankers. “It was a success,” says Stan. “We demonstrated that LNG could be safely transported and was a reliable alternate fuel source.”

The need to ship LNG by tanker across the province prompted Tilbury to develop training programs for anyone who would be in a position to handle it. “We felt responsible,” says Stan. “At that time, few people outside of Tilbury knew anything about how to safely handle LNG.”

The interest in using LNG as an alternative fuel eventually grew to include transportation customers. “There was an evolution,” says Jim. “After oil prices skyrocketed, about 10 years ago, LNG became an even more attractive option because as a fuel it’s quite a bit cheaper than oil.” Tilbury began providing LNG as a fuel for trucks and buses in 2010. “Momentum really picked up when companies with large fleets were offered incentives to make the switch,” says Jim.

Other types of customers soon followed, such as BC Ferries and Seaspan Ferries. Both have already converted some of their vessels to run on LNG, and plan to switch more. Starting in 2017, Tilbury began to supply LNG for shipment to China.

The Tilbury LNG Expansion project got underway in 2014 to support the evolving LNG needs of FortisBC’s customers. The first phase of the expansion, including a second storage tank 1.67 times larger than the original, and additional LNG production equipment, is now in service.

The expansion will help FortisBC continue to provide fuel for remote BC communities, local industry, overseas markets and to keep BC warm on cold winter days. Jim Cox believes it will have a far more reaching impact. “Essentially, the expansion will assist customers that are ready to switch from diesel to a cleaner burning fuel.”