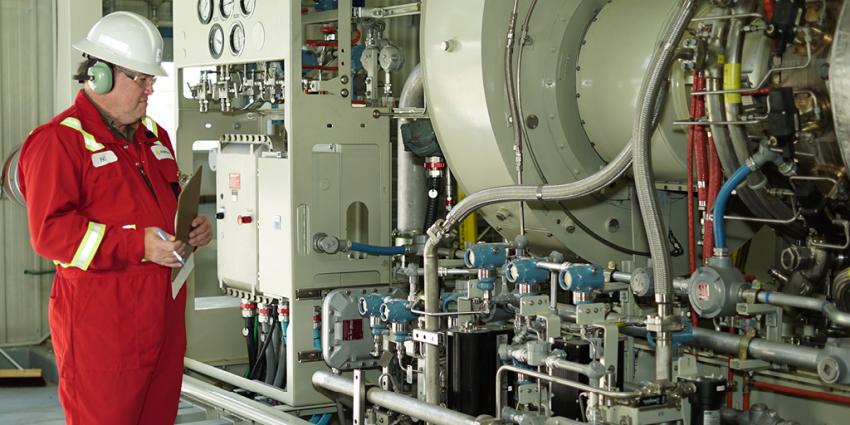

The stations are staffed and monitored by highly trained FortisBC personnel like Patrick (Pat) Reilly. It’s his job as a Compression and Controls Technician to keep the facility operating safely year-round. We asked him what it’s like to work at a FortisBC natural gas compressor station and why they’re important.

What is your job?

To operate and maintain the equipment at the coastal compressor stations to allow for the safe delivery of the high pressure natural gas to our customers on the pipeline. My colleague Howard Andres and I are mainly responsible for the Port Mellon and Texada compressor stations. When the workload demand at other stations requires more help, we’ll also assist at the Coquitlam or Langley compressor stations.

What does an average day look like at a FortisBC natural gas compressor station?

During peak load times when the turbine gas compressor is running, we monitor the operation of the turbine and the support equipment at the station. When the peak load demand is down to normal or low summer loads, we carry out any required maintenance on the turbine and the support equipment.

Why are natural gas compressor stations important to FortisBC’s system?

If we didn’t have compressor stations the pressure at the end of the line in Victoria would drop too low for reliable customer delivery. The station at Coquitlam is able to supply the larger amounts most of the time, but during higher demand days it’s necessary to run the additional units at Port Mellon and Texada to ensure safe and reliable delivery to all of our 108,000 customers from Squamish to Victoria.

Most customers probably don’t realize it, but the demand for natural gas can change from day to day or by the hour—sometimes by as much as 46 million cubic feet within that timeframe—for example, if BC Hydro needs to start up its cogeneration facility on Vancouver Island to balance out any upsets in its power system. When demand goes up, we need to move more gas through our system. The best way to maintain the pressure on the FortisBC system is to start and run the gas compressors to move this extra gas down the line.

What special knowledge or training does a person need to be an effective compression and controls technician?

An instrument, electrical or millwright trades ticket is essential for this job. My background is as a millwright with gas turbine experience. Before coming to FortisBC, I worked for Solar Turbines—the supplier of the units at Coquitlam, Port Mellon and Texada—for a total of 27 years. I was a senior field service representative for 19 years. Before that, I worked in the overhaul shop and test cells in Edmonton.

What is your approach and priority when it comes to safety?

Safety is a mindset and a culture that is essential to working safe and going home unhurt every night. I take time to thoroughly look at the job at hand and work through the job in my mind to see what could go wrong, and what will prevent problems.

For larger jobs we hold a tailgate meeting at the start or when the conditions change during a job. At tailgate meetings we go over the key points of the job and identify areas of concern. We develop a work plan and revise it as needed.

Is there anything else you would like people to know about compressor stations or natural gas in general?

Our compressor stations use the most recent and updated technology available. As a result, we’re operating some of the lowest-emission gas turbine equipment made today.

Coastal compression is a small part of FortisBC but if you look at our record, our constant commitment to our safety culture is clear. The compressor stations are monitored by FortisBC gas control 24 hours a day, 365 days of the year. If there are any problems at the individual stations they can be shut down and made safe within minutes. That includes the unlikely event of a gas leak or fire.

Part of our job is to test our emergency procedures on monthly, tri-monthly and annual basis. Our safety record for coastal compression speaks for itself: we haven’t had a major injury or incident in all our years of operation.