BC’s LNG advantages

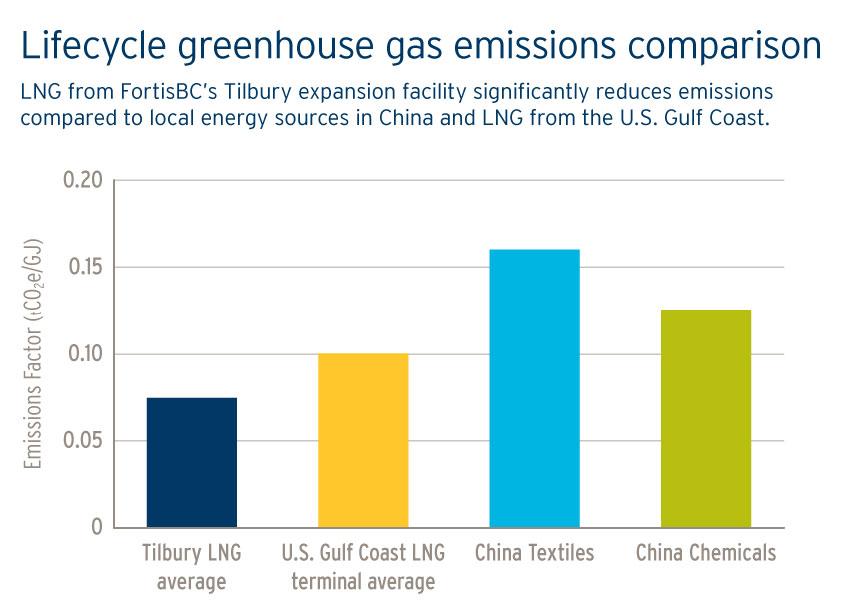

The study highlights the benefits of reducing global GHG emissions by exporting BC LNG produced at FortisBC’s Tilbury facility to industrial consumers in China. LNG from Tilbury could reduce lifecycle GHG emissions in Chinese industry from 30% to 50% depending on a number of factors. The study found BC LNG from Tilbury has a much lower carbon intensity than LNG from one of our closest competitors, the U.S. Gulf Coast. BC has a number of advantages that minimize carbon leakage such as closer proximity to eastern Asia, cleaner electricity, colder climate, and natural gas reserves with lower carbon content. All of these factors mean that the carbon intensity of producing natural gas, liquefying and shipping it is approximately half that of an average facility on the U.S. Gulf Coast while being more cost-competitive. This means that on a lifecycle basis, including all activities involved in the production, transportation and end use of energy, LNG from Tilbury achieves 25% more GHG emissions reductions than if it came from the U.S. Gulf Coast.

One of the most significant differences between LNG from Tilbury and from the Gulf Coast is the carbon intensity of gas extraction at the well. BC's regulations are some of the most progressive oil and gas regulations anywhere in the world, and as a result the carbon content of gas from BC’s reserves is, on average, lower than basins in the U.S.

Another factor is that Tilbury is connected to an electric grid that is powered almost entirely by renewable hydroelectricity. This significantly reduces emissions and makes Tilbury amongst the lowest carbon intensity LNG facility in operation around the world.

Tilbury’s GHG reduction potential

One of the factors behind growing global LNG demand is its potential to improve air quality and reduce lifecycle GHG emissions. A number of studies have been produced to quantify this potential, including a 2018 paper by researchers at John Hopkins University and the University of Calgary, which produced a lifecycle emissions analysis of LNG from Kitimat and concluded that those exports could reduce GHG emissions by up to 52.6 million tonnes per year when used for generating electricity in China, depending on the electricity mix displaced.

FortisBC contracted University of Calgary researcher Adebola Kasumu to develop an analysis using publicly available sources, such as the Pembina Institute’s shale scenario tool, a lifecycle GHG assessment for the entire LNG supply chain to China. FortisBC provided detailed data on the performance of the Tilbury facility as well as in-depth knowledge of LNG export activities, the gas system and BC’s gas market.

Tilbury made history in 2017 by producing LNG for the first shipment of Canadian LNG to China from its legacy LNG facility, which has been operating since 1971. Since then, FortisBC has been producing LNG for spot shipments by ISO container (a standard-sized shipping container). In July 2019, the facility’s first export contract was completed to supply Top Speed Energy with LNG for shipments of 60 ISO containers per week.

The analysis looked at the lifecycle emissions reduction potential of LNG ISO container shipments from Tilbury to China. The findings highlight Tilbury’s important role in the move to low-carbon energy showing that for every tonne of emissions in producing LNG in BC, two tonnes of GHG are reduced for China’s industries if they use LNG instead of local energy such as coal.

Export expected to grow, reducing GHGs and improving air quality

Customers from Asia are purchasing LNG produced at Tilbury is to displace coal as a source of energy for heating, industrial processes and power generation.

They’re also interested in LNG’s environmental benefits beyond just GHG emissions. A number of studies have found that using LNG instead of other fossil fuels for energy can significantly reduce air pollution. When compared to coal, gas consumption eliminates sulfur emissions and drastically reduces emissions of nitrogen oxide and particulate matter which are major factors in air quality.

China led the world with 18% year over year growth in gas consumption in 2018 as it prioritized switching from coal to gas to address air pollution and reduce GHG emissions. The International Energy Agency projects that China will account for 40% of gas demand growth to 2024. This growth is driven primarily by Chinese policy in the 13th Five Year Plan which focuses on switching industry, residential buildings and power from coal to gas.

LNG has a significant role to play in the worldwide transition to a lower-carbon economy. It is a flexible fuel that can be used to fuel ships and trucks, heat homes and power industrial processes. But the lifecycle emissions involved in producing the LNG varies. By analyzing the lifecycle emissions of LNG from the Tilbury facility, FortisBC can conclude that on a lifecycle emissions basis, its LNG has significant potential to reduce global GHG emissions and is among the lowest carbon intensity in the world.