Tilbury Phase 1 LNG Expansion project

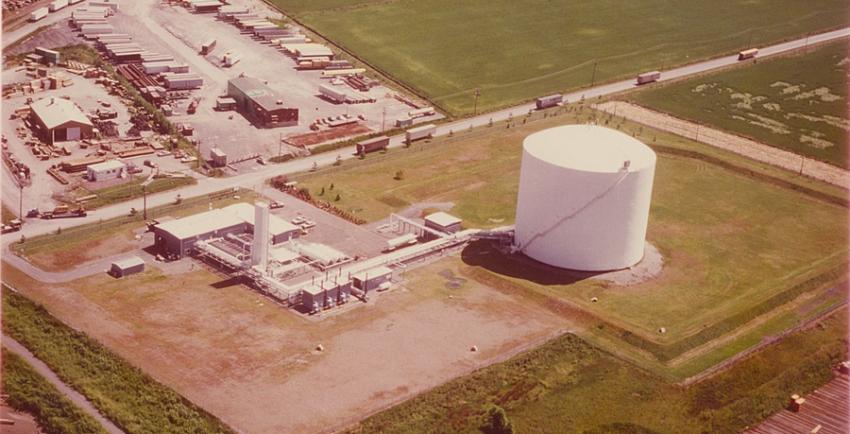

We’re proud to be operating the first ever liquefied natural gas (LNG) facility in British Columbia.

About this project

Our Tilbury LNG facility is powered by renewable hydroelectricity, creating safe, lower-carbon LNG since 1971. Originally, the facility’s purpose was to store LNG to ensure our customers have the energy they need even during high winter demand.

Now, it's producing LNG for transportation including for BC Ferries and Seaspan Ferries. As the demand for LNG as a marine fuel grows, we are also working with the Vancouver Fraser Port Authority to develop the first ship-to-ship LNG marine refuelling service on the west coast of North America. Our facility is also the first in Canada to produce LNG for export to China.

Current expansion

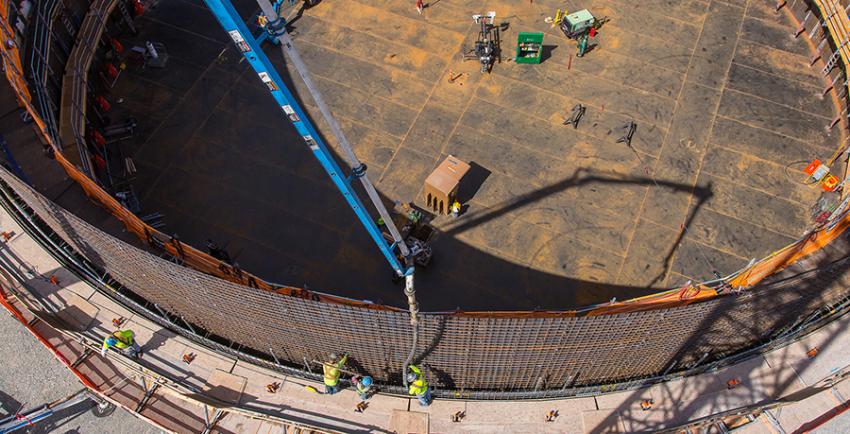

In 2018, we commissioned Phase 1 of an expansion to our facility including:

- a 46,000 cubic metre storage tank, enough to keep a community of 19,000 warm for 45 very cold days

- liquefaction capacity of 0.25 million tonnes of LNG per year

We’re continuing to expand our facility including:

- up to 0.65 million tonnes of liquefaction capacity to meet rising demand for LNG as a marine fuel

- a one-to-three-kilometre gas line upgrade from our facility to the Tilbury gate station on River Road in Delta

Next steps

The additional liquefaction capacity is in an early planning phase. Construction could begin as early as 2026.

The gas line upgrade is in the planning and design stages. We're exploring a number of route options and we’ll be engaging with the community on the upgrade.

The power line would connect a new substation at the Tilbury site with a BC Hydro substation in Ladner. We’re working with the City of Delta and the Ministry of Transportation and Infrastructure on a route that minimizes potential impact to private land.

Construction of Phase 1 could be complete as early as 2028.

Creating jobs and economic opportunities

The expansion of our Tilbury LNG facility in Delta is providing significant economic and employment benefits for the people of Delta, neighbouring communities and Indigenous communities. This includes more than $151 million in spending with BC suppliers.

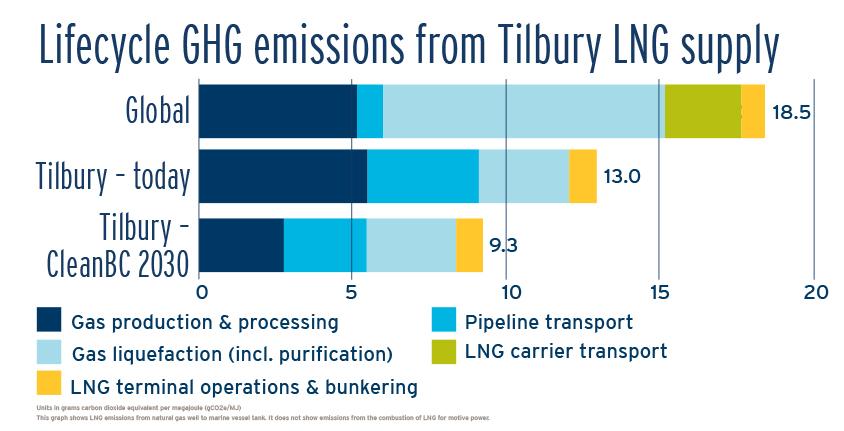

Reducing carbon emissions

Chinese industrial customers can reduce GHG emissions 30% to 50% if they switch from domestic sources of energy such as coal to LNG from Tilbury. Learn more about our analysis.

Tilbury through the years

In addition to our Tilbury LNG Expansion project, other companies are advancing LNG locally.

Tilbury Pacific marine jetty

The Tilbury Jetty Limited Partnership is building a marine jetty next to FortisBC’s Tilbury LNG storage facility that would allow the supply of LNG to vessels for ship-to-ship LNG bunkering, helping to decarbonize the marine shipping sector. For more information, visit tilburypacific.ca.

January 27, 2023

Snuneymuxw First Nation and FortisBC Holdings Inc. sign agreement for Tilbury LNG projects, strengthening long-standing relationship

August 10, 2022

Musqueam Indian Band and FortisBC Holdings Inc. sign Tilbury LNG Projects Agreement

December 16, 2021

FortisBC applies to extend existing air quality permit

April 8, 2021

Air quality permit amendment approved

December 17, 2020

FortisBC launches project to double LNG loading capacity at Tilbury

August 13, 2020

FortisBC applies for air quality permit amendment

July 16, 2019

FortisBC secures first export contract for Tilbury LNG

May 31, 2019

Routine maintenance for Tilbury legacy facility

May 22, 2019

Tilbury Expansion now in service

March 21, 2019

Environmental assessment filed for proposed Tilbury Pacific LNG project

December 14, 2017

BC companies making waves with Canada’s first shipment of LNG to China

November 22, 2017

First shipment of LNG from Canada to China launches from BC

August 20, 2017

Statement on incident at Tilbury expansion

June 20, 2017

Updated local economic and employment benefits

March 3, 2017

Expansion of Tilbury LNG plant nearing completion

December 16, 2016

LNG Tank - ready for hydrostatic testing

October 9, 2016

Power line upgrade

June 13, 2016

Tilbury LNG expansion creating jobs and benefiting local communities

February 3, 2016

Cold Box delivery at site

October 28, 2015

LNG tank - roof air raise

June 1, 2015

Start of processing area system installation

January 1, 2015

Ground reinforcement of processing area

December 16, 2014

Start of LNG tank construction

October 21, 2014

Construction begins on $400-million expansion project at Tilbury

July 28, 2014

Bechtel selected as contractor for $400-million Tilbury expansion project

January 31, 2014

Ground reinforcement of tank area

November 28, 2013

Tilbury expansion boosted by government announcement

Will the Project provide local jobs and other economic benefits?

Answered on:

Feb 27, 2020

When will the Project be in service?

Answered on:

Feb 27, 2020

What environmental benefits will the Project provide?

Answered on:

Feb 27, 2020

Who do we contact if we have more questions about the Project?

Answered on:

Feb 27, 2020

What is LNG and is it safe?

Answered on:

Feb 27, 2020

What happens if there is a leak?

Answered on:

Feb 27, 2020

What safety measures will be in place?

Answered on:

Feb 27, 2020

Could LNG have an impact on water or soil?

Answered on:

Feb 27, 2020

Why are you expanding the Tilbury LNG facility?

Answered on:

Feb 27, 2020

FortisBC supports the communities where we live and work. A big part of that is providing support for local organizations and the great work they do in the community. Here are some of the organizations in the City of Delta we've supported recently.

Delta Community Animal Shelter

Free seminars for animal lovers, children calmly reading books to purring cats, dogs frolicking in an off-leash fenced yard…no, this isn’t a spa for pets. This is the Delta Community Animal Shelter, and it’s changing perceptions of what an animal shelter can be.

FortisBC has been an ongoing sponsor of the shelter including providing funding for the opening of an agility centre and public off-leash area in 2019.

OWL (Orphaned Wildlife) Rehabilitation Centre

Of the 650 to 700 birds of prey that come through its door every year, OWL is able to successfully rehabilitate and release more than 50 per cent back into the wild. Others may be kept at the centre permanently to help with public outreach and education programs in schools, such as long time OWL resident Sonsie, a male bald eagle who is an “education ambassador” for the OWL Rehabilitation Centre.

The OWL Centre received a Community Giving contribution from FortisBC at the 2018 Union of BC Municipalities convention. The award allowed the centre to purchase more life-saving lead poisoning test kits for birds.

Reach Child and Youth Development Society

In 2016, FortisBC presented the Reach Child and Youth Development Society with $10,000 for their Building for Children Together project. This venture will see that a new child development centre is built to ensure children with disabilities and diverse abilities have a safe and accessible location for support.

In 2016, a donation was presented to the Rotary Club of Ladner, and will go towards a brand new water park located in Memorial Park. The upgrade is critical for this park due to safety issues, including an old concrete floor surface.

The water park is directly across from the new Reach Child Development Centre, and the families it supports will be frequent users of the park.

The expansion of our Tilbury LNG facility is creating jobs and economic benefits for local and Indigenous tradespeople, with 1,700 tradespeople registered for work on the expansion project.

Tom Sigurdson, former Executive Director, BC Building Trades, speaks about how the Tilbury LNG expansion project employs a high number of skilled trades.

FortisBC is proud to work with the Tsawwassen First Nation (TFN) Construction/Matcon Civil Joint Venture, which provides civil construction site services for our Tilbury LNG facility expansion in Delta. In this video, Chris Hartman, CEO of Tsawwassen First Nation Economic Development Corporation, talks about how local and Indigenous tradespeople are benefiting from the expansion.

We're also supporting First Nations training and employment opportunities through:

- 25 work experience/employment training programs provided by TMJV, FortisBC's civil engineering contractor (majority owned by the Tsawwassen First Nation)

- 48 Tsawwassen First Nation students have participated in training programs

Interested in working on this project? Fill out our contractors and vendors form.

Apprenticeship program provides economic and employment opportunities

When Tsawwassen resident Clyde Adams was preparing to return to the Lower Mainland, he contacted the Tsawwassen First Nations Human Resources department to inquire about employment opportunities. Adams knew they could help him connect with companies that reach out to First Nations communities when they’re looking for workers. They suggested he contact Bantrel, the contractor responsible for FortisBC’s Tilbury Phase 1 LNG Expansion Project. Read his story.

When I grow up, I want to be a scaffolder

Samantha Ethier never saw herself in the role, but she’s an apprentice scaffolder on the Tilbury Phase 1 LNG Expansion Project, and loving it. She’s always been athletic and willing to try new sports, so when her brother-in-law suggested she try scaffolding as a profession (he was a foreman with a scaffolding company) she accepted the challenge. Read her story.