Quick links

Building the foundation of BC’s energy future

The work we are doing today to improve our system will help us support BC’s tomorrow, as we shift towards a lower-carbon future. In the future, gas lines that currently deliver predominantly natural gas will increasingly supply renewable alternatives such as Renewable Natural Gas1. We are working with customers to reduce their greenhouse gas emissions and supporting the Province’s Roadmap to 2030.

Working to maintain and upgrade our gas system

While there are various reasons we complete work on our system, there are generally two main types of projects:

- Gas line construction: This includes building, upgrading and maintaining the lines we use to deliver gas to customers’ homes and businesses, such as the FortisBC Gas Line Upgrades project that was completed in 2020. FortisBC owns and operates more than 50,000 kilometres of gas line throughout BC.

- Facility and system upgrades: This includes building energy storage capacity such as the Tilbury and Mt Hayes liquefied natural gas (LNG) facilities, or enhancing our system so it can be inspected using the latest technology, such as the work currently underway on our Inland Gas Upgrades project.

Project stages

Our projects typically go through three key stages that help ensure we deliver them successfully and they meet the needs of both our customers and the communities where they are taking place. These are:

- Planning and regulatory: This is where we identify the need; start planning key elements such as scope, location and route; begin engaging with customers, stakeholders and Indigenous communities; complete site and environmental investigations; and apply for regulatory approval.

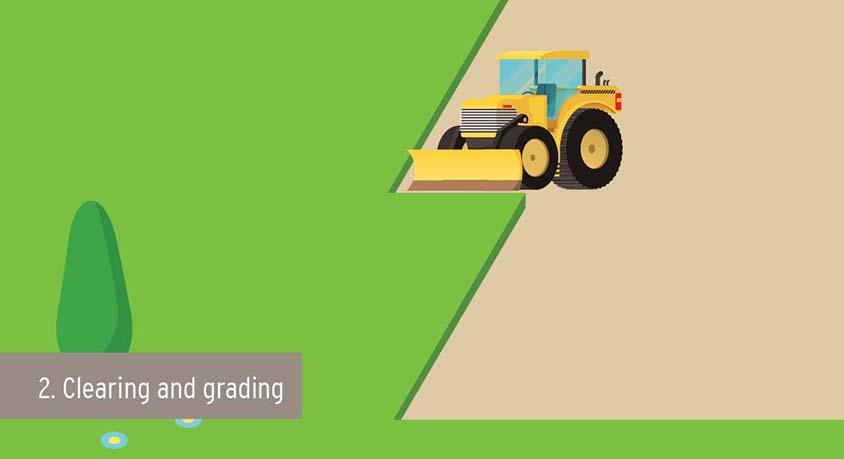

- Construction: This is when the project is built, from early works such as clearing vegetation and preparing for excavation to construction and bringing the new asset into operation. Often this is when people notice our projects.

- Restoration: Once construction is complete, we ensure we properly restore the areas we worked in. This means leaving the areas in as good – or better – condition than before we arrived, from replanting vegetation to restoring roads and driveways.

Gas line construction

We use two main construction methods for our gas line projects: open cut and trenchless. Combined these give us the flexibility to deliver projects safely, as quickly as possible and with the least disruption possible under a range of circumstances.

Open cut construction

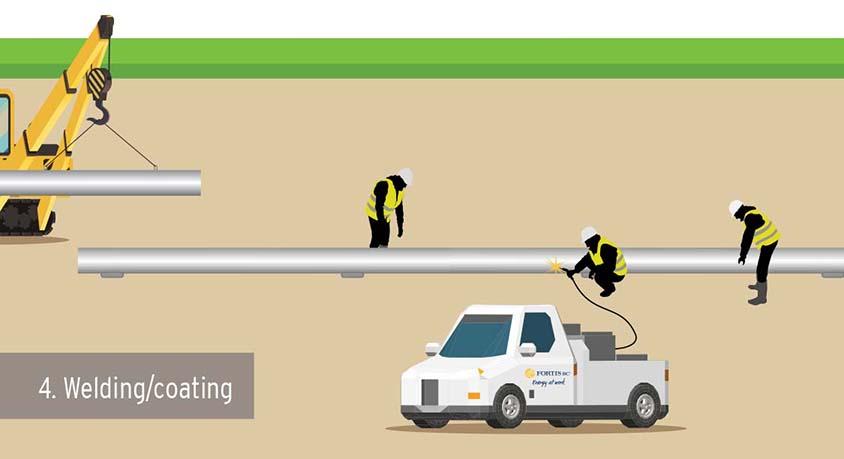

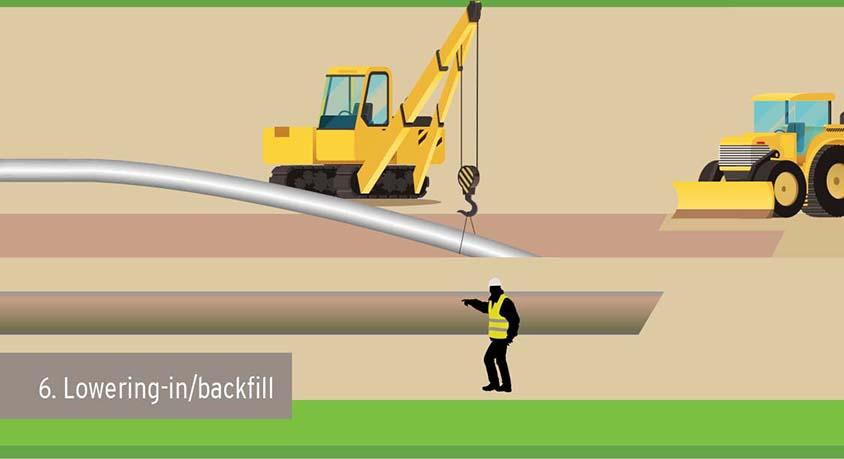

We use open cut, or trench, construction for the vast majority of gas line construction. Simply put this involves digging an open trench, lowering in the gas line, re-filling the trench and restoring the area. Open cut is a standard choice for gas line construction. It can be done safely and efficiently within the smallest amount of space.

At a typical open cut worksite you’ll see heavy equipment such as excavators, as well as long lengths of gas line waiting to be installed.

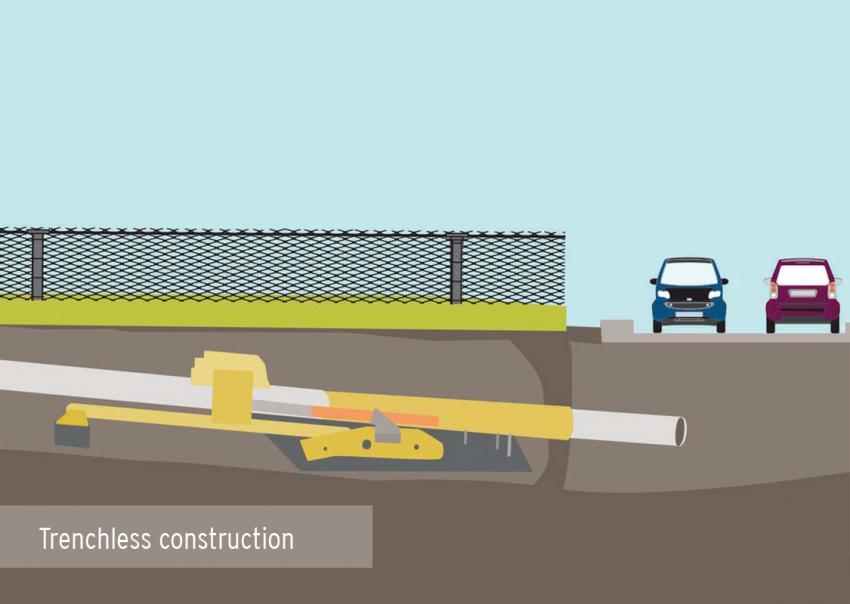

Trenchless construction

We use trenchless construction in locations such as where a gas line needs to cross a major road intersection, river or ecologically sensitive area. It involves installing our gas line using an underground borehole, leaving the surface undisturbed and minimizing disruptions.

Two worksites are required for trenchless construction, to send and receive the gas line underground. These are usually larger and deeper than those used for open cut construction.

1 Renewable Natural Gas (also called RNG or biomethane) is produced in a different manner than conventional natural gas. It is derived from biogas, which is produced from decomposing organic waste from landfills, agricultural waste and wastewater from treatment facilities. The biogas is captured and cleaned to create Renewable Natural Gas.